Wire Harness Testing 101: Continuity, Hi-Pot & Functional Tests Explained

The complete technical guide to wire harness testing methods, equipment, and standards. Learn how continuity, hi-pot, insulation resistance, pull force, and environmental tests ensure zero-defect production in 2026.

The $340,000 Testing Shortcut

In 2024, a Queensland mining equipment manufacturer received 2,000 wire harnesses from a low-cost supplier. The supplier performed "100% continuity testing" but skipped hi-pot testing to save $0.30 per unit—a $600 saving on the order.

Three months into field deployment, 47 harnesses failed catastrophically due to insulation breakdown, causing equipment fires and safety shutdowns. Total cost: $340,000 in replacements, downtime, emergency callouts, and regulatory investigations. The $600 "saving" became a six-figure disaster.

This guide explains why comprehensive testing is not optional—it's insurance against catastrophic failure.

Why Wire Harness Testing Is Critical

Wire harnesses are the nervous system of modern equipment—from vehicles to medical devices, industrial robots to mining machinery. A single defective wire can cascade into complete system failure, safety hazards, or regulatory non-compliance.

Testing Catches These Common Defects:

Continuity Testing

Continuity testing verifies that electrical connections are complete and have acceptably low resistance. It's the most fundamental test—ensuring current can actually flow from point A to point B.

How Continuity Testing Works

- 1.Test equipment applies low voltage (typically 5-12V DC) across each circuit path

- 2.Measures resistance to verify complete circuit (<1 ohm for most applications)

- 3.Detects open circuits (breaks), poor crimps, or wrong wire routing

- 4.Results compared against pre-programmed wiring diagram

What Passes

- • Resistance < 1 ohm (typical for good crimps)

- • All required circuits present

- • Correct pin-to-pin mapping

- • No unintended connections

What Fails

- • Open circuit (infinite resistance)

- • High resistance (> 1 ohm indicates poor crimp)

- • Missing wires or connections

- • Wrong wire in wrong terminal

Typical Test Parameters

| Test Voltage: | 5-12V DC (non-destructive) |

| Pass Criteria: | < 0.5 ohm (precision) to < 1.0 ohm (standard) |

| Test Current: | 100-500 mA (prevents contact welding) |

| Test Duration: | 0.1-1 second per circuit point |

| Industry Standard: | IPC/WHMA-A-620 Section 9.0 |

Hi-Pot (High Potential) / Dielectric Testing

Hi-pot testing applies high voltage (typically 500V-3000V) between conductors to verify insulation integrity. It's a stress test designed to catch insulation defects before they cause field failures, fires, or safety hazards.

Hi-pot testing is mandatory for products meeting UL, IEC 60950, and IEC 62368 safety standards. Skipping this test exposes end-users to electric shock risk and manufacturers to liability.

How Hi-Pot Testing Works

- 1.Test voltage calculated based on operating voltage: typically (2 × operating voltage) + 1000V

- 2.High voltage applied between conductor groups and ground for specified duration (1-60 seconds)

- 3.Leakage current monitored—excessive current indicates insulation breakdown

- 4.Test detects pinhole defects, contamination, and marginal insulation before field deployment

Common Test Voltages by Application

| Application | Operating Voltage | Test Voltage | Duration |

|---|---|---|---|

| Automotive 12V | 12V DC | 500-1000V | 1-2 sec |

| Industrial 24V | 24V DC | 1000-1500V | 1-5 sec |

| Medical Equipment | 120-240V AC | 1500-3000V | 5-60 sec |

| Industrial 240V | 240V AC | 2000-3000V | 1-5 sec |

| High Voltage | >400V | Custom per IEC | Per standard |

Note: Specific requirements per IEC 60950-1 and IEC 62368-1 safety standards

Pass Criteria

- • Leakage current < 1-5 mA (application dependent)

- • No arcing or breakdown during test

- • Voltage held for full duration

- • Post-test continuity still passes

Failure Indicators

- • Excessive leakage current (> limit)

- • Insulation breakdown (arcing)

- • Voltage cannot be sustained

- • Visible damage or discoloration

Insulation Resistance Testing

Insulation resistance (IR) testing measures the resistance between conductors at moderate voltage (typically 250-1000V). Unlike hi-pot's pass/fail stress test, IR testing quantifies insulation quality with a resistance reading (typically megohms).

Key Differences: Hi-Pot vs. Insulation Resistance

| Aspect | Hi-Pot Testing | IR Testing |

|---|---|---|

| Purpose | Stress test (pass/fail) | Quality measurement |

| Voltage | 500-3000V | 250-1000V |

| Result | Leakage current (mA) | Resistance (MΩ) |

| Typical Minimum | < 1-5 mA leakage | > 10-100 MΩ resistance |

Typical IR Test Acceptance Criteria

- Standard applications: > 10 MΩ minimum at 500V DC

- High reliability (medical, aerospace): > 50-100 MΩ at 500-1000V DC

- Automotive: > 50 MΩ per IPC/WHMA-A-620 requirements

- Trend monitoring: Decreasing IR over time indicates aging insulation

Pull Force / Crimp Quality Testing

Crimp quality is the #1 cause of wire harness field failures. Pull force testing verifies that terminal crimps can withstand mechanical stress during installation, vibration, and thermal cycling. Poor crimps may pass electrical tests initially but fail after weeks or months in service.

Pull Force Requirements by Wire Gauge (IPC/WHMA-A-620)

| Wire Gauge | Wire Diameter | Minimum Pull Force (lbs) | Minimum Pull Force (N) |

|---|---|---|---|

| 26 AWG | 0.40 mm | 3-5 lbs | 13-22 N |

| 24 AWG | 0.51 mm | 4-6 lbs | 18-27 N |

| 22 AWG | 0.64 mm | 5-7 lbs | 22-31 N |

| 20 AWG | 0.81 mm | 7-10 lbs | 31-45 N |

| 18 AWG | 1.02 mm | 10-15 lbs | 45-67 N |

| 16 AWG | 1.29 mm | 15-20 lbs | 67-89 N |

Reference: IPC/WHMA-A-620 Requirements and Acceptance for Cable and Wire Harness Assemblies

Destructive Pull Testing

Wire pulled until failure occurs. Used for first article inspection and process validation.

- • Verify crimp strength exceeds minimum

- • Confirm proper failure mode (wire breaks, not terminal pulls out)

- • Typically 5-10 samples per production batch

Cross-Section Analysis

Terminal and wire cut and examined under microscope to verify crimp quality.

- • Check wire strand compression (50-80% ideal)

- • Verify proper bell mouth formation

- • Detect insulation intrusion into crimp

Microscopic crimp cross-section analysis in our CNAS certified laboratory

Functional Testing

Functional testing verifies that the wire harness performs its intended function in a simulated operating environment. This goes beyond electrical verification to confirm the harness works correctly with actual connectors, loads, and signal requirements.

Common Functional Tests

Signal Integrity

Verify data transmission quality for communication cables

- • CAN bus signal quality

- • Ethernet data rates

- • USB signal verification

- • Impedance matching

Load Testing

Apply actual current loads to verify voltage drop and heating

- • Rated current for specified duration

- • Voltage drop < 3-5% at full load

- • Temperature rise monitoring

- • Connector temperature limits

Mating / Insertion Force

Verify connectors mate properly with appropriate force

- • Insertion force within limits

- • Proper locking mechanism engagement

- • Retention force verification

- • Repeated mating cycles (100-1000×)

Operational Simulation

Test with actual equipment or test fixtures

- • Integration with end equipment

- • Software/firmware compatibility

- • Error-free operation duration test

- • Multi-function simultaneous operation

When Functional Testing is Essential

- Complex control systems (automotive ECU harnesses)

- High-speed data transmission (USB, Ethernet, CAN)

- Medical device harnesses (regulatory requirement)

- High power applications (>10A continuous)

- Safety-critical systems (brake systems, airbags)

- Complex multi-connector assemblies (>5 connectors)

Environmental Testing

Environmental testing subjects wire harnesses to extreme conditions they'll face in real-world operation. These tests accelerate aging and reveal weaknesses that wouldn't appear in standard electrical testing.

Temperature Cycling

Exposes harness to extreme hot and cold cycles to verify material stability and joint integrity.

Humidity Testing

Verifies resistance to moisture ingress and corrosion in humid environments.

Vibration Testing

Simulates mechanical stress from vehicle operation, machinery, or transport.

Environmental Testing Frequency

Environmental tests are typically performed on pre-production samples (10-20 units) and repeated when materials, processes, or suppliers change. Not performed on every production unit due to destructive nature and cost. Results validate the production process.

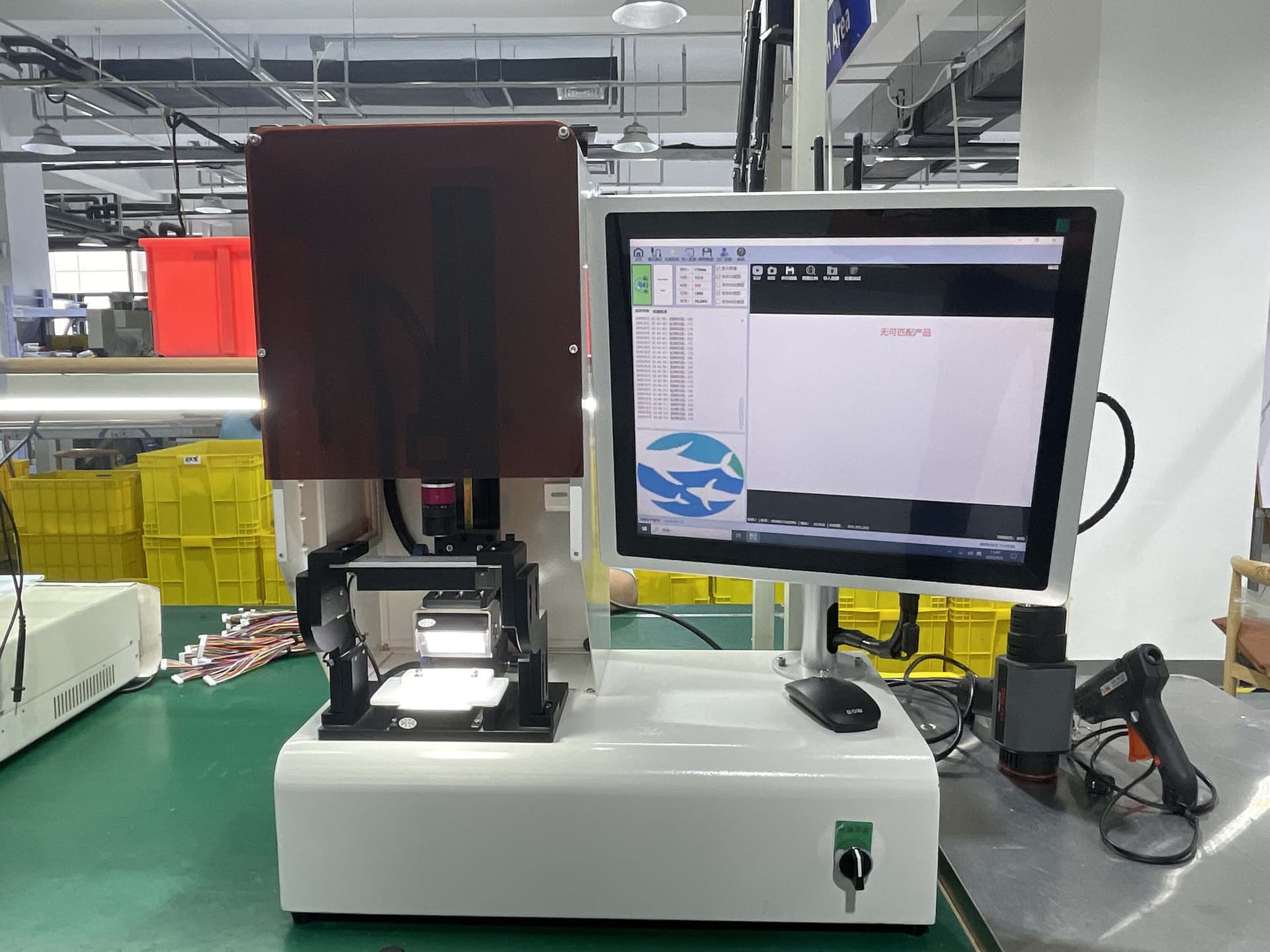

Wire Harness Testing Equipment

Professional wire harness testing requires specialized equipment. Quality manufacturers invest in automated testing systems that provide consistent, repeatable results and full traceability.

Automated Continuity Testers

Examples: Cirris testers, Dynalab systems, custom test fixtures

Hi-Pot / Dielectric Testers

Must comply with UL and IEC safety standards

Pull Force Testers

Calibrated per National Measurement Institute standards

Environmental Chambers

Enables accelerated life testing and qualification

Our CNAS Certified Testing Laboratory

OurPCB operates a CNAS (China National Accreditation Service) and ISO/IEC 17025 certified testing laboratory with international mutual recognition through ILAC-MRA. This means our test reports are accepted globally without retesting—saving Australian importers time and compliance costs.

Our Testing Capabilities & Equipment

Electrical Testing (100% Production)

- Automated continuity testing (512-point systems)

- Hi-pot testing: 500V-5000V AC/DC

- Insulation resistance: up to 10,000 MΩ

- Full traceability with barcode tracking

Mechanical Testing

- Pull force testing: 0-500N capacity

- Crimp cross-section analysis (microscopy)

- Connector insertion/retention force

- Durability testing (1000+ mating cycles)

Environmental Testing

- Temperature cycling: -70°C to +180°C

- Humidity testing: up to 98% RH, 1000 hours

- Salt spray testing: 500-1000 hours

- Vibration testing: 10-2000 Hz, up to 20G

Quality Standards Compliance

- IPC/WHMA-A-620 certified operators

- IATF 16949 automotive quality systems

- UL, IEC 60950, IEC 62368 compliance

- Internationally recognized test reports

Why CNAS & ISO/IEC 17025 Matters for Australian Importers

Our laboratory accreditation provides international mutual recognition through the ILAC-MRA agreement. This means our test reports are accepted by regulatory authorities in Australia and 100+ countries without requiring retesting. For Australian businesses, this translates to faster customs clearance, lower compliance costs, and confidence that products meet local standards including those set by the National Measurement Institute Australia.

CNAS Certified Lab

Automated Testing

Crimp Analysis

Frequently Asked Questions

What is the difference between continuity testing and hi-pot testing?

Continuity testing verifies that electrical connections are complete and have low resistance (typically <1 ohm), ensuring current can flow properly. Hi-pot (high potential) testing applies high voltage (500V-3000V) to verify insulation integrity and prevent short circuits between conductors. Both are essential: continuity confirms connections work, hi-pot confirms they won't fail.

What voltage should be used for hi-pot testing wire harnesses?

Test voltage depends on the wire harness operating voltage. Common formula: (2 × operating voltage) + 1000V. For example, 12V automotive systems typically use 1500V, while 240V industrial harnesses may require 2000-3000V. IEC 60950 and IEC 62368 standards provide specific requirements. Duration is typically 1-60 seconds at test voltage.

How often should wire harnesses be tested in production?

100% testing is standard for critical applications (automotive, medical, aerospace). Every harness undergoes continuity and hi-pot testing. Pull force and crimp quality use statistical sampling—typically first article, hourly checks, and last piece. Environmental tests are performed on pre-production samples and repeated quarterly or when materials/processes change.

What is an acceptable crimp pull force for wire harnesses?

Pull force requirements vary by wire gauge and terminal type. For example, 22 AWG typically requires 5-7 lbs (22-31N), 18 AWG requires 10-15 lbs (45-67N). IPC/WHMA-A-620 specifies minimum values. We perform pull testing on first articles and maintain statistical process control with hourly checks to ensure consistent crimp quality.

Do Australian wire harness manufacturers need CNAS certification?

While not mandatory, CNAS (China National Accreditation Service) or ISO/IEC 17025 laboratory accreditation provides international mutual recognition through ILAC-MRA. This means test reports are accepted globally without retesting. For Australian importers, working with CNAS-certified manufacturers reduces compliance costs and ensures testing meets National Measurement Institute Australia standards.

Can I request test reports for my wire harness order?

Yes. We provide comprehensive test reports including continuity test results, hi-pot test data, pull force measurements, and environmental test results (when applicable). Reports include serial numbers, test parameters, pass/fail criteria, operator signatures, and timestamps. Test data is archived for 5+ years for traceability.

Get Wire Harnesses with Guaranteed Testing Quality

Every OurPCB wire harness undergoes 100% continuity and hi-pot testing in our CNAS certified laboratory. We provide complete test reports, traceability, and compliance documentation. Melbourne office support means you get answers fast.

Related Articles

How to Choose a Wire Harness Manufacturer

8 key factors including quality control and testing processes.

IP67 vs IP68 vs IP69K Ratings

Understanding waterproof ratings for harsh environments.

Automotive Wire Harness Cost Breakdown

What drives pricing in automotive harness manufacturing.