Quality Certifications & Standards

ISO 9001:2015, IATF 16949:2016, ISO 13485:2016, and AS/NZS certified manufacturing ensuring world-class quality for Australian industries.

Our Quality Certifications

Recognized international standards ensuring consistent quality and compliance across all products

ISO 9001:2015

International quality management system standard ensuring consistent product quality and customer satisfaction.

- Certified since 2018

- Annual surveillance audits

- Continuous improvement processes

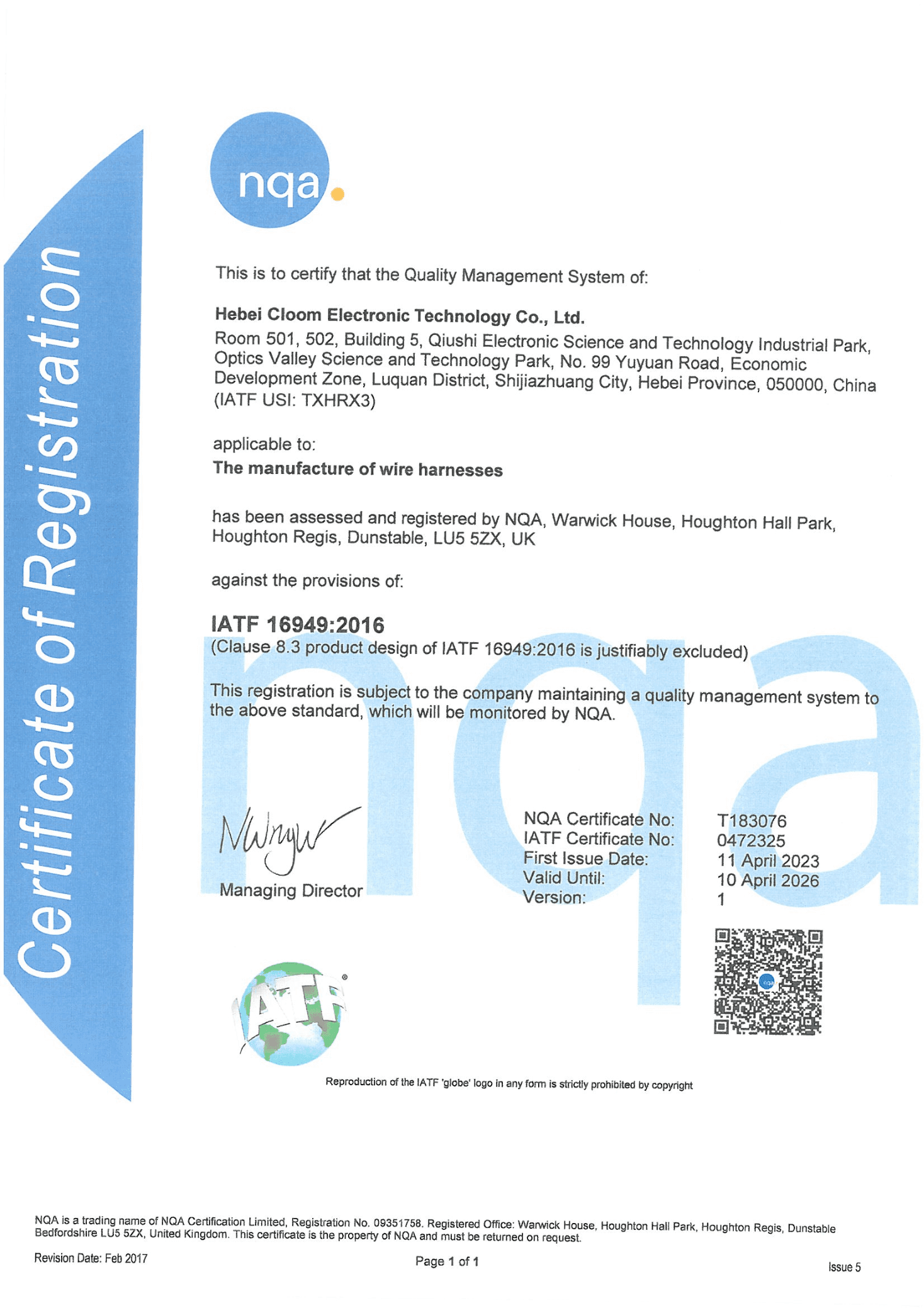

IATF 16949:2016

Automotive quality management system for automotive industry suppliers worldwide.

- Full PPAP capability

- APQP process implementation

- Automotive OEM approved

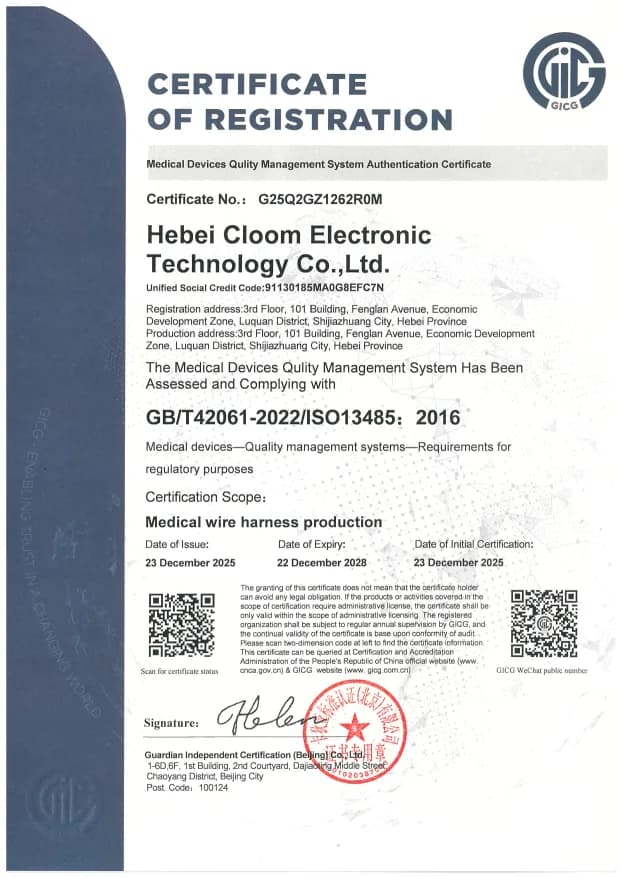

ISO 13485:2016

Medical device quality management system for design, development, and manufacturing of medical wire harnesses.

- Medical device compliant

- Risk management processes

- Full traceability systems

Our Quality Process

Comprehensive quality control at every stage from design to delivery

Design Review

DFMEA analysis, design validation, and specification review before production.

Incoming Inspection

100% material verification, supplier quality audits, and component testing.

In-Process Control

Statistical process control, first article inspection, and continuous monitoring.

Final Testing

Comprehensive electrical, mechanical, and environmental testing before shipment.

Advanced Testing Capabilities

Our fully-equipped testing laboratory ensures every cable assembly meets or exceeds industry standards and customer specifications.

Electrical Testing

Continuity, insulation resistance, hi-pot testing up to 5000V, contact resistance verification

Mechanical Testing

Pull force testing, insertion/extraction cycles, crimp analysis, tensile strength verification

Environmental Testing

Temperature cycling, humidity resistance, salt spray, vibration testing per automotive standards

Dimensional Verification

Precision measurement equipment, 3D scanning, first article inspection reports

Product Testing Coverage

First Pass Yield

Defect Rate

Testing Coverage

Quality Response Time

8D Problem Solving & CAPA Process

When quality issues occur, we don't just fix them—we find root causes, implement corrective actions, and prevent recurrence through systematic 8D methodology.

Our 8D Process

Team Formation

Cross-functional team assembled with subject matter experts from engineering, production, and quality.

Problem Definition

Detailed problem description using 5W2H (What, When, Where, Who, Why, How, How Many).

Interim Containment

Immediate action to isolate defects and protect customers while root cause investigation continues.

Root Cause Analysis

5-Why analysis, fishbone diagrams, and data analysis to identify true root causes.

Permanent Corrective Actions

Design and implement solutions that eliminate root causes and prevent recurrence.

Verification & Validation

Test corrective actions to ensure effectiveness through production trials and statistical validation.

Preventive Measures

Update procedures, work instructions, training programs, and quality systems to prevent similar issues.

Team Recognition

Document lessons learned and recognize team contributions to continuous improvement culture.

CAPA: Corrective & Preventive Action

Our systematic approach to problem resolution ensures issues are not just fixed, but prevented from recurring across all operations.

- Documented tracking system for all quality events

- Root cause analysis within 48 hours

- Effectiveness verification and follow-up

- Preventive actions applied across similar products

Response Time to Quality Issues

Our quality team is available around the clock to address your concerns and implement immediate corrective actions.

Related Resources

Related Articles

Our Capabilities

Ready to Experience Our Quality Commitment?

Get a free quality consultation and learn how our certified processes can benefit your project.

Contact Quality Team